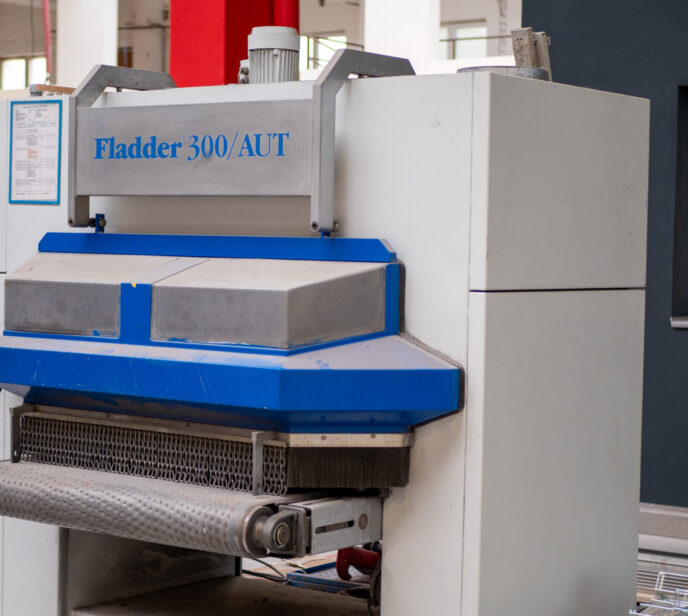

Good grinding and careful deburring is not only of aesthetic importance, but can also have an important influence on the function of the component. In addition, the process is important for the safe handling of the parts. At Prostor Design, we use a deburring grinder from Fladder for this purpose.

About FLADDER 300/AUT

The FLADDER 300/AUT offers an unbeatable combination of high performance and simple operation. Parts are ground by a grinding head with 6 spindles, which rotate in pairs in opposite directions, on a vacuum conveyor belt. The grinding head also rotates around its own axis and oscillates over the entire conveyor belt.

On the conveyor belt, workpieces are held in place by two vacuum turbines with the aid of a vacuum system. This can also securely hold small parts without any problems. The discharged air is returned to the finished ground workpieces at the exit, where it cleans them.

To simplify operation, the machine has a digital display and a window through which the grinding process can be monitored. If necessary, adjustment corrections can be made continuously even during operation.

Advantages of the Fladder 300/AUT

- All motors are controlled by frequency converter, which saves energy (and costs).

- Robust and simple design minimizes sources of error and maintenance costs

- Simple operation

- Reliable high quality performance

+420 388 314 321

+420 388 314 321  obchod@prostor-design.cz

obchod@prostor-design.cz