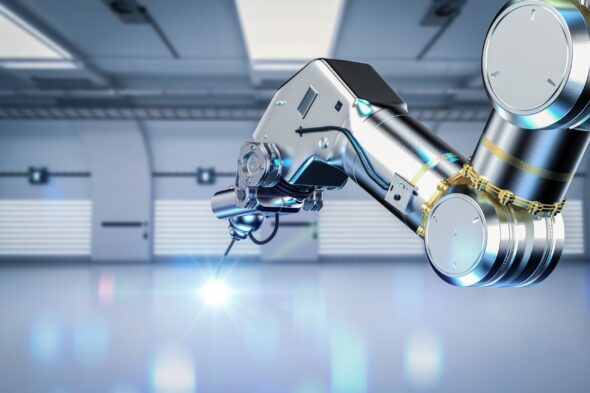

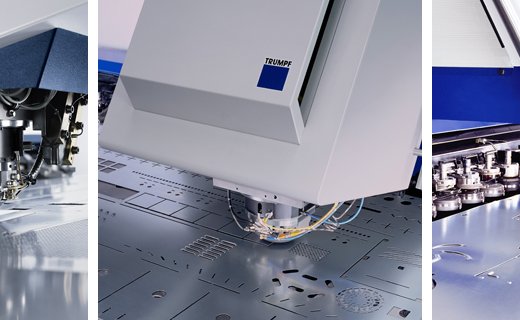

This compact welding cell enables us to carry out welding processes efficiently (and therefore cost-effectively) even for small batches. The welding robot ensures consistent quality results.

Flexibility and Efficiency

The system has a 2-station workpiece positioner with horizontal changeover and rotary and swivel motion. This means that during the automatic welding process in the welding area, the next process in the insertion area can already be prepared. The welding technician is protected by the lateral safety fence and a light barrier during the cycle.

When the welding process is finished, the table is changed so that the finished part can be removed and the next one prepared. This largely automates the process and maximizes labor productivity.

Advantages of robotic welding with the CLOOS compact cell

- Very fast – efficient welding

- Consistent quality for all parts

- Production of defect-free parts

- Suitable also for small batch production

- MIG/MAG and TIG/WIG welding at one workstation

- Suitable for welding aluminum, stainless steel, steel

+420 388 314 321

+420 388 314 321  obchod@prostor-design.cz

obchod@prostor-design.cz