At Prostor Design we produce precision punched parts on our CNC machines from TRUMPF (TruMatic, TruPunch). This enables us to cut, punch, form, die-cut and slit sheet metal according to precise dimensions.

These functions are important for the production of various parts and products, as well as for fastening other elements in the processed sheet metal. Precise threading and punching, for example, is necessary for high-quality further processing of the sheet metal parts, so that screws, bolts and other securing elements fit well and can possibly be effectively pressed in or welded.

Our sheet metal technology

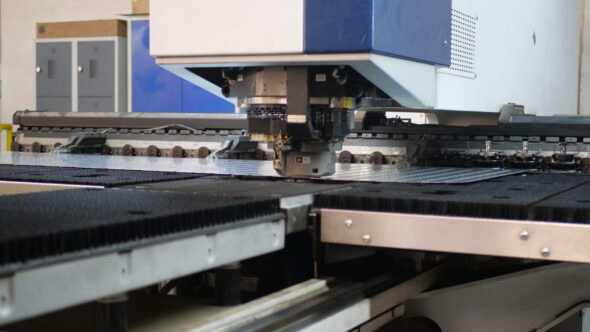

Thanks to the most modern CNC machines (TruMatic 6000 and TruPunch), at Prostor Design we offer simultaneous sheet metal forming, i.e. threading, punching – threading hole, form punching, and pressing of stiffening ribs and air ribs. By performing several processes simultaneously, production becomes faster and more economical, and therefore less expensive. If necessary, we can create very small bends and work precisely with thin sheets, or with thicker sheets with a maximum thickness of 4mm.

The high performance of the punching head on our TruMatic 6000 CNC machine enables high product quality and productivity when processing steel sheets, galvanized sheets, stainless steel sheets or aluminum sheets. But the machine also has an impressive CO2 laser cutting quality, which combines laser sheet metal processing, sheet metal splitting and punching.

If you are interested in how we can help you with your project, please feel free to contact us!

+420 388 314 321

+420 388 314 321  obchod@prostor-design.cz

obchod@prostor-design.cz